About Me

I want to make high impact in Manufacturing/Quality/Reliability. Achieved 100% on time delivery and 96% quality with 4+ years of work experience, working for OEM's and consulting firms. I enjoyed collaborating and connecting with various departments internally, connecting with suppliers and vendors externally to provide exceptional attention to applied technologies, which ensures flawless operation with high customer focus, to bring exponential growth and productivity.

I believe in the concept of Design Thinking and a fan of the book written by CEO of IDEO Tim Brown, where he explains the importance of team work, communication and ideas. I provided creative design and innovative manufacturing possibilities to reduce manufacturing costs by 20%. Activities varied from client presentations, CAD modelling, manufacturing concepts to 3D printing, Rapid prototyping, and Hazard Assessments and Quality control and validations.

Started my career with bachelors in Mechanical Engineering, realized the need for broader perspective and greater knowledge. This excitement to learn new subjects and methods made me pursue my Master’s in Industrial Engineering from Texas A&M University, College Station.

KEY SKILLS: • Electrical, Mechanical, Industrial systems • Continuous Improvement • Advanced Quality Control • Root Cause Analysis • Lean Manufacturing • Data Analysis/ Data Interpretation • Statistical Process Control • Purchasing & Procurement • Value Stream Mapping • Supplier Quality • Six Sigma Green Belt • FMEA/5S/Kaizen • GD&T • CAD Modelling/ Solid Works/ CATIA • DMAIC • Value Addition/ Value engineering • Process automation.

If you are looking for an individual who can provide exceptional attention to applied technologies, which ensures flawless operations through incredible designs, that enable manufacturers, service providers, and supply chain professionals to bring about exponential growth and productivity, feel free to connect with me.

My Skills

Exceptional skills results in innovative solutions. Over the years I have put effort to move out of my comfort zone to develop skill-sets that would help me create high impact in the industry. Gained high proficiency in various domains such as process, industrial, manufacturing, data and quality.

New Product Development

Data Analysis

Quality Assurance

Lean Manufacturing

Process Planning

INDUSTRIAL

Production & Inventory Control

Multidimensional issues faced in modern industry for inventory control were handled and a tool was developed to address these issues. Human factors and ergonomic ideas were closely complemented while developing this tool.

Data Analysis

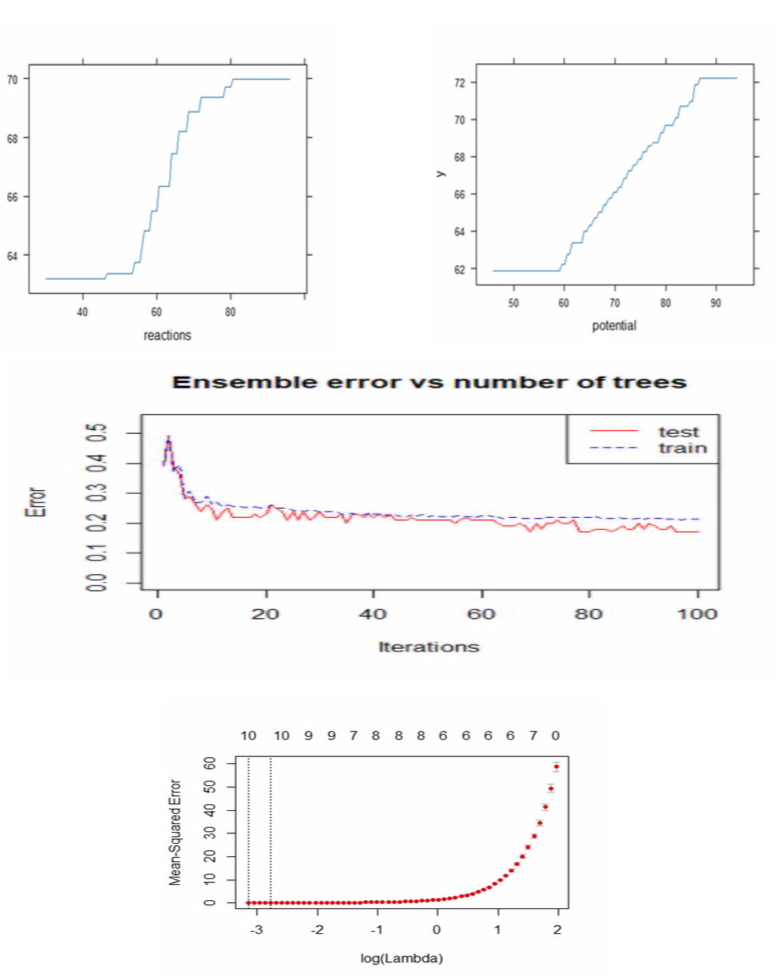

Handled large manufacturing and performance data to make calculated decisions and presented it to customers and senior management. Various basic techniques such as PCA, regression were used to predict the overall performance and to classify items. The cross validation errors were calculated to rate the results.

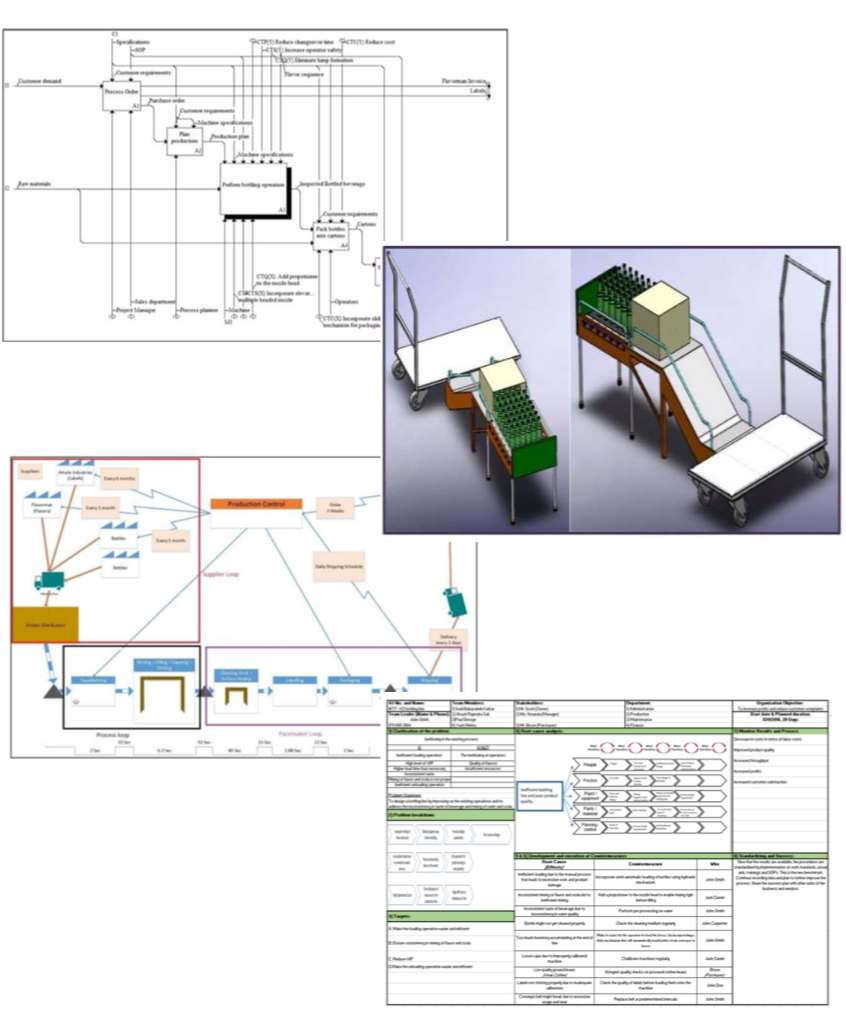

Lean Production Line/Lean Manufacturing

Multiple solutions to establish high impact in lean production line was suggested to the customer. Statistical Process Control techniques was established for advanced quality. No cost, low cost, high cost solutions with quality study was implemented with the help of amazing tools such as SOP, FMEA, A3, IDEF models,CAD tools etc.

MECHANICAL

Engine Manufacturing

Developed complete 3D definition for Aero engine casings. We worked on over 6000 dimensions for a 5" X 5" component implementing GD&T to achieve a 95% quality. Developed the complete process plan to manufacture the component using latest machinery (Transfer of Technology).

Jig and Fixture Design

Developed fixture concepts and models to support CNC machines and CMM machines to perform with the best efficiencies. This supported to transform the industry to latest technology (Industrie 4.0).

CMM Programming & Simulation

Created CMM program and tools to achieve high quality of the manufactured components. Developed First article inspection reports which were automated to analyze and compare the results obtained from the CMM machine.

ELECTRICAL

Electrical Wiring Interconnection System

Wire harnessing and routing was done for Aircrafts. Interior design for aircrafts to manage the wiring connections. Developed VBA excel tools to analyze the connected ports.

Reliability Engineering

Analyzed the independent requirements of the flight control system using a top down approach with the help of Fault tree analysis. Common mode analysis was done to identify the components that would lead to catastrophic or hazardous events.

Wind Energy Harnessing

Developed complete wind turbine design including maintenance equipments. Nascelle, tower & hub were the focus. Sheet metal, surfacing and solid fabrication was involved in the process.

Projects

-

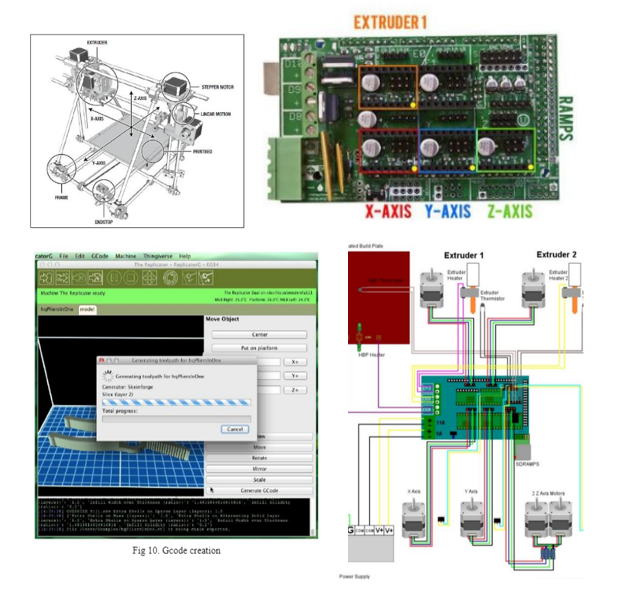

RepRap 3-D Printer

Lorem ipsum dolor sit amet, consectetur adipiscing elit

-

Inventory Planning Tool

Lorem ipsum dolor sit amet, consectetur adipiscing elit

-

KPI / Manufacturing Data

Lorem ipsum dolor sit amet, consectetur adipiscing elit

-

Lean Manufacturing

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Education

Work Experience

IKO Southwest

JUNE 2019 - DECEMBER 2019

Manufacturing COOP Engineer

- Liaison between reliability, maintenance and production teams, and yield a 100% production run time by applying lean methods.

- Manage equipment spare parts list, drawings, database connecting vendors and suppliers in CMMS, to achieve 100% efficiency.

- Apply Kaizen, 5S, created SOP's, standard work chart for production team. New system helps to recover OEE to 98%

TEXAS A & M University

AUG 2018 - MAY 2019

Student Assistant NYE Academic Center

- Tutor in mathematics and statistics.

- Helped establish base in statistical process control and data analytics for undergrad students.

L & T Technology Services

OCT 2014 - MARCH 2018

Manufacturing Engineer

- Led Wind Turbine team of 6. Introduced new processes to improve quality, customer and management appreciation was well received for innovations. Managed data pertaining to manufacturing and created reports. Designs- Jig, fixtures & parts – sheet metal, surfacing, solids.

- Shadowed leaders to understand flight control, hydraulic and landing gear breaking systems. Integrated and analyzed simplified FTA from PSSA for aircrafts using a top down approach to arrive at basic events. Electrical Wire Interconnection System. Implemented continuous improvement plan. Introduced Macros. Performed Common Mode Analysis (CMA) to eliminate redundancy. Quality standards understood for RCA.

- Process Planning plus Manufacturing and Operational Tooling. Transfer of Technology (Industrie 4.0). First Article Inspection Report AS 9102: document dimensions of precision engine components using Inspection Expert for quality. Six sigma implementation. Statistical Process Control. Developed & utilized CAD Model, Detailed, Validated complex engineering drawings (Solid Works), CMM Programming (PC DMIS 2014), and 3D Printing of precision Aero components (FDM, Stratasys)

- Customer appreciation for 140% efficiency in completing the projects. Kaizen principle used. Recorded 100% on-time delivery and 98% quality over the 3.5 years of work tenure. KPI identified. Over 20 fixture designs completed and accepted by customer; Aided 20% manufacturing cost reduction. Certified in GD & T; Abstracts and ideas on Rapid Prototyping short listed for white paper in Tech Panorama event conducted in L&T TS

SCHUNK METALS AND CARBONS

JULY 2013 - AUG 2013

Manufacturing Intern

- Manufactured carbon based electrical components. Was in charge of electrical bracket production. Was exposed to design, quality and production.

COCHIN PORT TRUST

JUNE 2013 - JULY 2013

Maintenance Intern

- Performed maintenance activities for the GHD Nehru - Dredger ship engine room. Sailed for a month. Learned how to deal with emergency situations.

APOLLO TIRES

JULY 2012 - AUG 2012

Facility Intern

- Involved in the inventory management and map routing of trucks in the facility. Got familiar with the production technology of tires

UAE EXCHANGE

JULY 2012 - AUG 2012

Programming Intern

- Developed computer programs using VB.Net as front end and SQL as back end. Programming knowledge has been always helpful throughout my career.

Paul is very focused and dedicated towards his work. Extremely good in communication and completes activities precisely within stipulated time ! Very good interpersonal skills !!Prafulla Jagtap, Project Manager at L & T Technology Services

Paul was part of my team for more than an year. He is smart and highly dependable resource with very good inclination towards learning new things. He is good at improvising things and making sure that mistakes don't repeat. I can always expect on-time deliverables meeting the very stringent and tight dead lines. He has niche talent and good communication skills. Vinod Kumar, Project Lead at L & T Technology Services

Paul is a very hard worker and quick learner. He is an excellent team player and coordinates very well with the team. His contribution towards the team and projects are always immense and doesn't mind working in odd hours to complete the work.Arun Karthic, Senior Design Engineer at L & T Technology Services

Contact

- 311 Stasney Street, Apt 1104

- +19797030940

- vpaulg@gmail.com

- Download My Resume